Hydraulic breaker

Hydraulic breaker referred to as "broken hammer" or "breaker". Hydraulic breaker’s power sourc is excavators, loaders or pumping stations’ pressure. It can break stones and rocks more effectively in the engineering construction. Selection of hydraulic breaker principle is according to the operation environment and excavator type.

Get a Free Quote

Description

Hydraulic breaker referred to as "broken hammer" or "breaker". Hydraulic breaker’s power source is excavators, loaders or pumping stations’ pressure. It can break stones and rocks more effectively in the engineering construction. Selection of hydraulic breaker principle is according to the operation environment and excavator type.

Excavator Hydraulic Breaker Features

● Efficient power transfer:Optimum transfer of blow energy into the materia and the reduction of the recoil.

● Wear wel working tool: Heat treated and optimal for efficient breaking.

● Quality parts: Attach importance to the rel ability of each parts

● Precision assembly: Measure the standard size

Excavator Hydraulic Breaker Bracket Type

Carrier Type

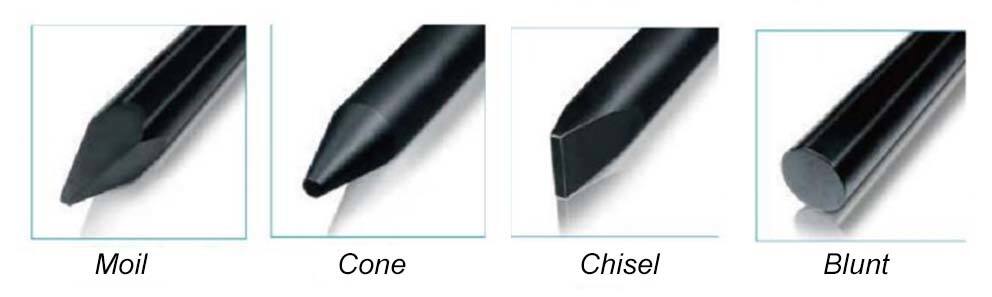

Working Tool

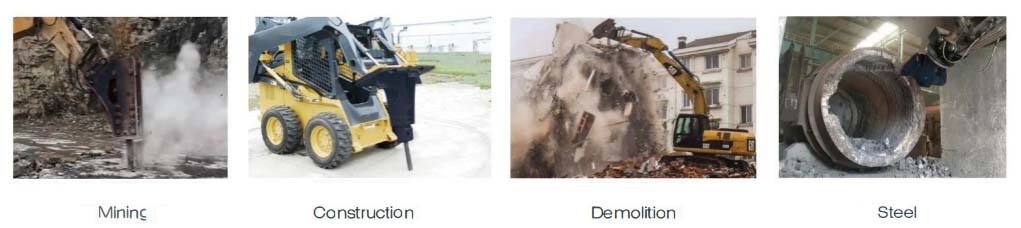

Excavator Hydraulic Breaker Application

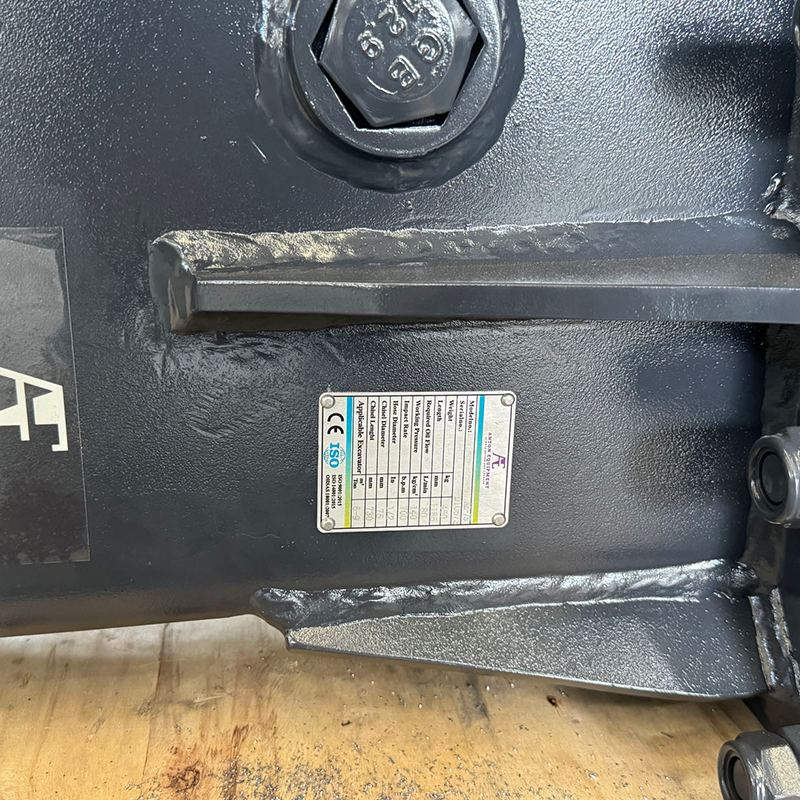

Parameter

| Working principle | ||||

| Key novelty | Slight twisting effect Good footage performance Achieve excellent wedging effect in four directions |

No twisting effect Good footage performance Excellent wedging effect in all directions |

Strong twisting effect Good footage performance Obtain the best wedging effect in both directions |

Optimal energy transfer No twisting effect No footage performance No wedging effect |

| For concrete | Non reinforced concrete | Non reinforced concrete | reinforced concrete | Recycling (steel bar separation) |

| For sedimentary rock operation | Mainly used for crushing small fissured Ningshi and whole rocks | Mainly used for crushing small fissured rocks and whole rocks | Mainly used for crushing large fractured rocks | Secondary crushing (crushing large rocks) |

| For metamorphic rock/volcanic rock | Mainly used for crushing large fractured rocks |

Mainly used for crushing small fissured rocks or whole rocks, as well as for secondary crushing |

Excavator Hydraulic Breaker Specification:

| Model | Unit | AEA45S | AEA53S | AEA68S | AEA75S | AEA85S | AEA100S |

| Weight(side type) | Kg | 90 | 120 | 250 | 380 | 510 | 765 |

| Weight(box type) | Kg | 110 | 135 | 292 | 450 | 580 | 890 |

| Oil flow rate | bar | 90-120 | 90-120 | 110-140 | 130-160 | 130-160 | 150-170 |

| Oil pressure | Lpm | 20-40 | 25-50 | 40-70 | 50-90 | 60-100 | 80-110 |

| Tool diameter | mm | 45 | 53 | 68 | 75 | 85 | 100 |

| Blows per minute | Bpm | 700-1200 | 600-1100 | 500-900 | 400-800 | 400-800 | 350-700 |

| Rubber tube diameter | inch | 1/2 | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 |

| Weight of carrier | ton | 1.2-3 | 2.5-4.5 | 4-7 | 6-9 | 7-14 | 11-16 |

| Model | Unit | MHA135S | MHA140S | MHA150S | MHA155S | MHA165S | MHA175S | MHA190S | MHA195S | |

| Weight(side type) | Kg | 1062 | 1462 | 1740 | 2144 | 2413 | 2650 | 3915 | 4719 | 4881 |

| Weight(box type) | Kg | 1210 | 1675 | 1861 | 2237 | 2838 | 3065 | |||

| Oil flow rate | bar | 150-170 | 160-180 | 160-180 | 160-180 | 160-180 | 160-180 | 160-180 | 160-180 | 160-180 |

| Oil pressure | Lpm | 80-110 | 100-150 | 120-180 | 150-210 | 180-240 | 200-260 | 210-290 | 230-320 | 230-320 |

| Tool diameter | mm | 125 | 135 | 140 | 150 | 155 | 165 | 175 | 190 | 195 |

| Blows per minute | Bpm | 500-900 | 350-600 | 350-500 | 300-450 | 300-450 | 250-400 | 150-250 | 150-250 | 150-250 |

| Rubber tube diameter | inch | 3/4 | 1 | 1 | 1 | 1 | 1 1/4 | 1 1/4 | 1 1/4 | 1 1/4 |

| Weight of carrier | ton | 12-16 | 16-21 | 18-26 | 25-30 | 28-35 | 30-45 | 40-55 | 45-70 | 45-70 |

Videos

FAQs

Question:Which country have you been exported?

Reply:Russia, USA, Canada, Japan, Korea, Malaysia, Hong Kong, Taiwan, India, Indonesia, Australia, New Zealand, Israel, South Africa etc.

Question:How about the Shipment?

Reply:Shipment can be made by sea, air or land. Sea loading ports include Qingdao, Yantai and Shanghai etc. Sales manager will select an optimal shipping method for you. For more information, please contact with customer service staff.

Question:How about the package?

Reply:Our attachments are packaged by standard export wooden cases free from fumigation.

Question:How about delivery time?

Reply:Usually 15 days subject to order quantity. Due to the surge in orders, please check with customer service staff for lead time.

Question:What’s the MOQ and payment terms?

Reply:MOQ is 1 set. Payment by T/T

Question:Can I customize a product?

Reply:Sure, we can provide OEM and ODM service.

Question:Are you sure your product will fit my excavator?

Reply:Yes, we are professional attachments manufacturer, We make attachments according to your excavator bucket dimensions.

Question:Are you a manufacturer?

Reply:Yes, our factory was established in 2004.